Mondja meg a nyomtató, mi az a mélynyomtatás?

We've been talking about our traditional printing, album printing and promotional printing. Of course, for us to print, we may know what products can be printed in our own factory and those products can't be printed. If some customers don't know them, they will also encounter such problems. Come and consult us. Printing is a universal project with strong universality. What we haven't touched is a little hard to understand, including what is gravure printing in our printing. Today, Panyu printing factory will introduce intaglio printing to understand.

Gravure printing is one of the four printing methods. Gravure printing is a direct printing method. It prints the ink in the gravure pit directly on the substrate. The thickness of the printing picture depends on the size and depth of the pit. If the pit is deep, the ink will be more, and the ink layer left on the substrate will be thicker. On the contrary, if the pit is shallow, the ink will be less, and the ink left on the substrate will be thicker The layer will be thinner.

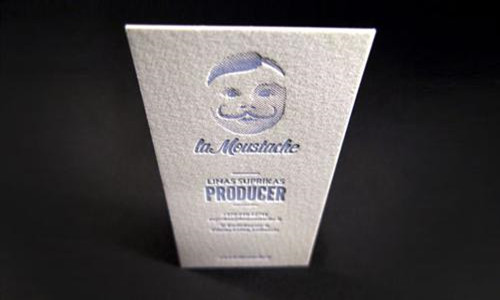

Embossing Cardboard Box

Gravure printing is composed of the pits corresponding to the original and the plate surface. When printing, the ink is poured into the pits, and the ink on the plate surface is scraped off with a scraper. The plate contacts with the substrate under a certain pressure, and the ink in the pits is transferred to the substrate to complete the printing.

From the perspective of application, gravure printing is mainly used for fine publications such as magazines and product catalogues, packaging printing, banknotes, stamps and other securities printing, as well as special fields such as decorative materials; in China, gravure printing is mainly used for soft packaging printing. With the development of gravure printing technology in China, gravure printing has also been widely used in paper packaging, leather materials and pharmaceutical packaging. The main disadvantages of gravure printing are: complex pre press plate making process, long cycle, high plate making cost; high harmful gas content in workshop due to the use of volatile solvents, great harm to workers' health; the treatment of gravure printing required Brush practitioners are relatively high, etc.

These are some basic introductions of intaglio printing from Panyu printing factory. We seldom use them in traditional printing. I hope the above introduction can help customers in need. The workers in the gravure printing workshop should be prepared for protection. Gravure printing is different from other printing, it has better anti-counterfeiting effect, so we need more time and energy. Hope to give you more understanding. If you want to know more, welcome to our website!